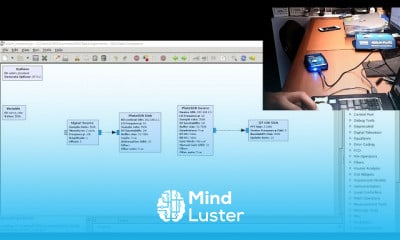

A Distributed Control System (DCS) is an advanced control system commonly used in industrial settings. It consists of a network of controllers and devices that work together to manage and automate processes across multiple locations. Unlike traditional centralized systems, where one controller oversees the entire operation, a DCS distributes control tasks among several controllers. This architecture enhances reliability, flexibility, and scalability.

Key Features of DCS

1. Decentralization: Each controller manages a specific part of the process, allowing for localized control. This minimizes the risk of a single point of failure.

2.Real-Time Monitoring: DCS enables continuous monitoring of processes, facilitating immediate responses to changes and optimizing operations.

3. Human-Machine Interface (HMI): Operators can interact with the system through user-friendly interfaces that display real-time data, alarms, and control options.

4. Integration of Technologies: Modern DCSs often incorporate advanced technologies like artificial intelligence and machine learning to enhance decision-making and predictive maintenance.

Also see 23 Main Types of Bearings

Learning About DCS

1. Educational Background: A solid foundation in engineering, particularly in fields like electrical, mechanical, or chemical engineering, is beneficial. Courses on control systems, automation, and instrumentation are highly relevant.

2. Hands-On Experience: Practical experience with control systems through internships or lab work is invaluable. Familiarity with programming languages and software used in DCS environments (like MATLAB or PLC programming) is crucial.

3. Online Resources: Numerous online courses and tutorials cover DCS concepts, design, and implementation. Websites like Coursera, edX, and specialized industrial training platforms offer courses tailored to various skill levels.

4.Professional Certifications: Obtaining certifications in automation and control systems (like those offered by ISA or similar organizations) can enhance your knowledge and credibility in the field.

5. Networking: Joining professional organizations or forums related to industrial automation can provide insights, resources, and connections within the industry.